Most Popular Products

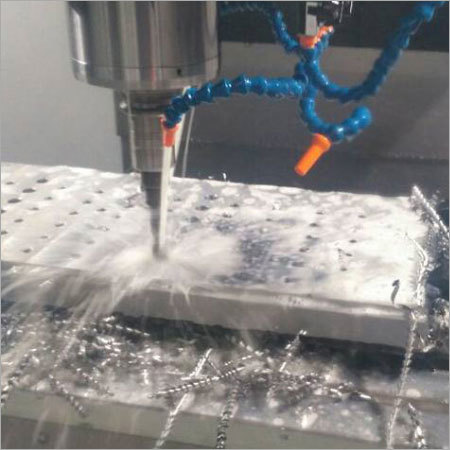

VMC Milling Works

Price 10000 INR/ Number

MOQ : 1 Number

VMC Milling Works Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1 Number Per Day

- Delivery Time

- 1 Days

About VMC Milling Works

VMC Milling Works is a leading provider of high-quality milling services using Vertical Machining Centers (VMCs). With state-of-the-art machinery and a team of skilled technicians, we offer precision machining solutions for a wide range of industries. Our commitment to delivering superior results, combined with our expertise and advanced equipment, makes us the preferred choice for all your milling needs.

FAQs:

Q: What is VMC milling?

A: VMC milling refers to the process of removing material from a workpiece using a vertical machining center. It involves using rotating cutting tools to shape and contour the workpiece into the desired shape.

Q: What industries can benefit from VMC milling works?

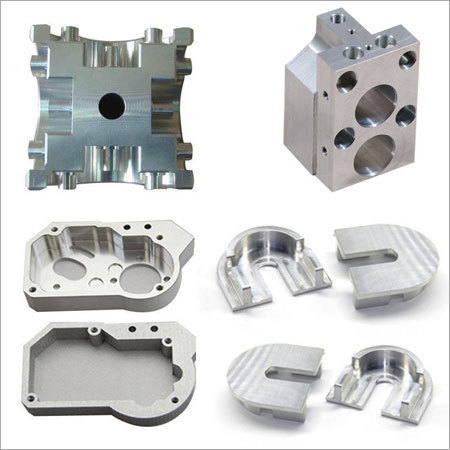

A: VMC milling works are highly versatile and can be utilized across various industries such as aerospace, automotive, medical, electronics, and many more. It is commonly used for manufacturing components, prototypes, molds, and precision parts.

Q: What sets VMC Milling Works apart from other milling service providers?

A: At VMC Milling Works, we pride ourselves on our commitment to excellence. Our team of experienced technicians has extensive knowledge in milling operations and utilizes state-of-the-art VMC machinery to ensure superior results. We also prioritize customer satisfaction and strive to deliver projects within specified timelines.

Q: What materials can be milled using VMC?

A: VMC milling works can handle a wide range of materials, including metals (aluminum, steel, stainless steel, titanium, etc.), plastics, composites, and even certain types of wood. The versatility of VMC machinery allows us to accommodate various material requirements.

Q: How accurate are the milling services provided by VMC Milling Works?

A: Our VMC milling services are known for their precision and accuracy. With advanced CNC controls and cutting-edge measuring instruments, we can achieve tight tolerances and meet even the most demanding specifications

Precision Engineering for Demanding Applications

VMC Milling Works offer exceptional cutting accuracy and consistent quality for sophisticated machining projects. The expansive travel range combined with a customizable fixture system ensures adaptability for varied job requirements. Each unit is engineered for reliability, supporting high spindle speeds while maintaining micro-level tolerances. Companies across India trust our solutions for their precision milling needs.

Reliability and Performance at the Core

With an integrated coolant system and robust power requirements, our VMC Milling Works are built for continuous operation and high-duty work cycles. Whether handling complex components or high-load parts, the machine's capabilities ensure productivity remains high without compromising on precision or surface finish. Customers benefit from long-term durability and efficient performance.

FAQ's of VMC Milling Works:

Q: How does the VMC Milling Works achieve high precision in machining?

A: The VMC Milling Works utilizes a CNC controller paired with a spindle speed of up to 6000 RPM and cutting accuracy of 0.01 mm. Combined with X, Y, and Z travels of 1000, 500, and 500 mm, and an integrated coolant system, the machine consistently delivers precise and reliable results for intricate engineering tasks.Q: What types of projects is this VMC suitable for?

A: This VMC is ideal for a wide array of projects requiring precise milling, such as manufacturing automotive components, aerospace parts, and high-accuracy industrial equipment. Its customizable fixtures and substantial table load capacity make it suitable for both small parts and heavy, complex assemblies.Q: When should I consider using this VMC Milling Works?

A: Consider utilizing this VMC Milling Works when you need accurate and repeatable milling processes, especially for parts demanding tight tolerances and large workpiece sizes. It is an excellent choice for industries needing high productivity and consistent quality over repeated cycles.Q: Where is this VMC Milling Works available and who can purchase it?

A: This product is available across India and can be sourced by manufacturers, fabricators, and service providers through our expansive network. As a distributor, exporter, manufacturer, service provider, supplier, and trader, we cater to both domestic and international enquiries.Q: What is the process for customizing fixtures on this machine?

A: Customization of fixtures involves understanding your specific job requirements. Our engineering team can design and install tailored fixtures to securely hold varied workpieces, ensuring optimal machining results while reducing set-up times and improving operational efficiency.Q: How is the VMC Milling Works powered and what are its electrical requirements?

A: The machine operates on a robust 415V, 3 Phase, 50Hz power supply. This industrial-grade configuration ensures both safe operation and reliable performance during extended working hours.Q: What are the primary benefits of using this VMC Milling Works?

A: The key benefits include remarkable cutting accuracy, high-speed operation, a large machining envelope, and reliable integration with customized fixtures. Additionally, the integrated coolant system and CNC control ensure enhanced surface finishes and reduced production times, making it an excellent investment for competitive manufacturing environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Milling Job Work Category

|

NIDHI POLY PLAST

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry